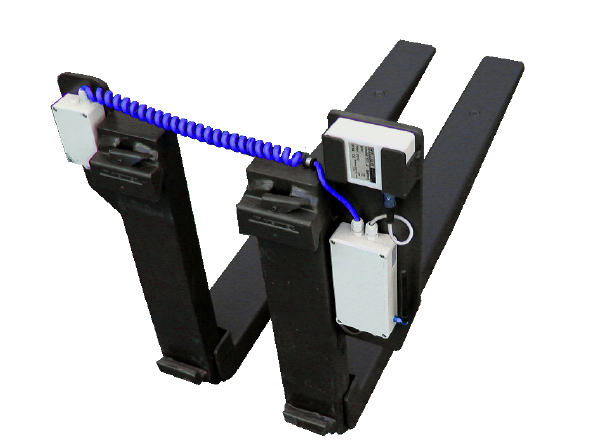

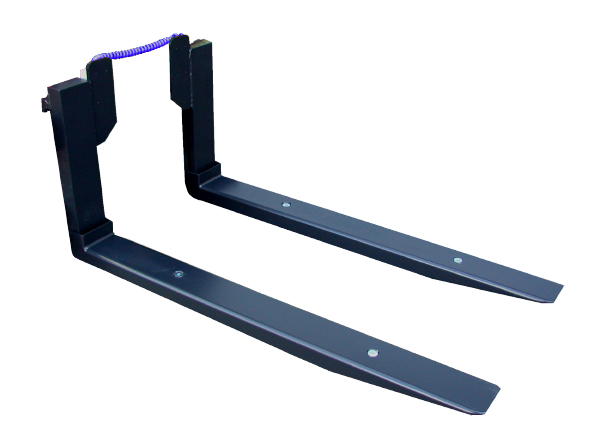

WEIGHING FORKS WG

Accuracy ±0,1% of the applied load

Weighing forks can be attached to any forklift with a FEM fork carriage. The weighing accuracy is very high and the system is designed so that the relatively rough truck use can not damage the weighing equipment. Signal transmission is standard via radio or spiral cable. The verifiable version is only allowed with cable connection. Also available in conjunction with a fork adjustment.

Features / Benefits

- Signal transmission standard via radio, alternatively with spiral or mast cable connection

- For wireless transmission a fast and cost-effective installation (only one battery in the transmitter up to 125 operating hours)

- Weigh at every lifting height

- 2 or 3 load cells in each fork ensure high accuracy

- Sturdy basic fork corresponds to a 3-fold safety

- Approved design including calibration certificate according to Class III and inclination sensor

- Protection class IP 65

Produktblad her

Produktblad her